Baolai Smart Grid

A focus on intelligent high and low voltage switchgear products research and development, manufacturing, sales, operation in one of the science and technology manufacturing enterprises

GGD type AC low-voltage distribution cabinet is suitable for power plants, substations, factories and mining enterprises and other power users of AC 50Hz, rated working voltage 380V, rated working current to 3150A power distribution system, as power, lighting and distribution equipment for energy conversion, distribution and control.

National hotline

+86-0557-3620199GGD type AC low-voltage distribution cabinet is suitable for power plants, substations, factories and mining enterprises and other power users of AC 50Hz, rated working voltage 380V, rated working current to 3150A power distribution system, as power, lighting and distribution equipment for energy conversion, distribution and control.

GGD type AC low-voltage power distribution cabinet is a new type of low-voltage power distribution cabinet designed according to the requirements of the department of Energy supervisor and the majority of power users and design departments, in line with the principles of safety, economy, reasonable and reliable. The product has the characteristics of high breaking capacity, good dynamic and thermal stability, flexible electrical scheme, convenient combination, series, practicability, novel structure, high protection level, and can be used as the replacement of low-voltage switchgear. GGD type AC low-voltage distribution cabinet conforms to IEC439 "Low-voltage switchgear and control equipment", GB7251 "low-voltage switchgear" and other standards.

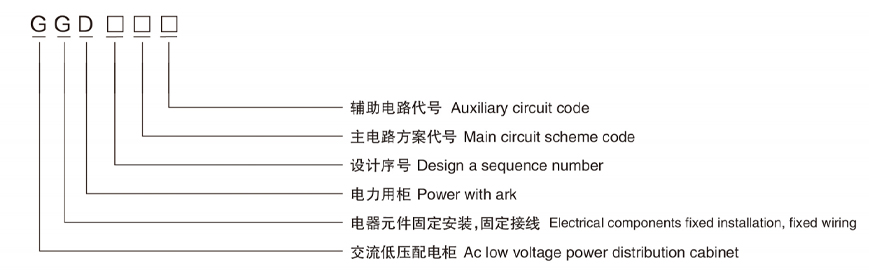

Model and meaning

Environmental conditions of use

The ambient air temperature shall not be higher than +40C, not lower than -5°C, and the average temperature within 24h shall not be higher than +35C;

For indoor installation and use, the altitude of the use place shall not exceed 2000m;

The relative humidity of the surrounding air should not exceed 50% at the maximum temperature of +40C, and a larger relative temperature should be allowed at lower temperatures (e.g. 90% at +20C), taking into account the effect of condensation that may occur occasionally due to changes in temperature;

The inclination between the equipment and the vertical plane shall not exceed 5°;

The equipment should be installed in a place without violent vibration and impact and not enough to corrode the electrical components; Users have special requirements can be negotiated with the manufacturer to solve.

Structural characteristics

(1) The GGD type AC low-voltage distribution cabinet adopts the form of a general cabinet, the frame is made of 8MF cold-formed steel by partial welding assembly, and the frame parts and special supporting parts are supplied by the section steel fixed point production plant to ensure the accuracy and quality of the cabinet. The components of the general purpose cabinet are designed according to the module principle and have 20 mold mounting holes. The high general coefficient can enable the factory to achieve pre-production, which not only shortens the production cycle, but also improves the work efficiency.

(2) The design of GGD cabinet fully takes into account the heat dissipation problem in the operation of the cabinet. There are different number of heat dissipation slots at both ends of the cabinet. When the electrical components in the cabinet are heated, the hot air rises and is discharged through the upper slot, and the cold air is constantly supplemented by the lower slot into the cabinet, so that the sealed cabinet forms a natural ventilation channel from the bottom up to achieve the purpose of heat dissipation.

(3).GGD cabinet in accordance with the requirements of modern industrial product design, the golden section ratio method is used to design the shape of the cabinet and the partition size of each part, so that the whole cabinet is beautiful and elegant.

(4) The cabinet door is connected to the frame with a rotating shaft movement chain, convenient installation and disassembly, and there is a mountain rubber and plastic strip at the hem of the door. When closing the door, the inlay strip between the door and the frame has a certain compression stroke, which can prevent the door from directly colliding with the cabinet, and also improve the protection level of the door.

(5) The instrument door equipped with electrical components is connected to the frame with multiple strands of soft copper wire, and the installation parts in the cabinet are connected to the frame with knurled screws, and the whole cabinet constitutes a complete grounding protection system.

(6) The top paint of the cabinet is made of polyester orange baking paint, which has strong adhesion and good texture. The whole cabinet is matte color, avoiding glare effect and creating a more comfortable visual environment for the staff on duty.

(7) The top cover of the cabinet can be removed when needed to facilitate the assembly and adjustment of the main bus line on site. The four corners of the top of the cabinet are equipped with hanging rings for lifting and loading.

(8) The protection level of the cabinet is IP30, and the user can also choose between IP20 and IP40 according to the requirements of the use environment.

Installation and use

After the product arrives at the receiving place, it should first check whether the packaging is complete and undamaged, and notify the relevant departments to find out the cause in time. Products that are not immediately installed should be placed in an appropriate place in accordance with the normal conditions of use.

Product installation

The installation of the product should be carried out according to the installation diagram, and the basic channel steel and bolts should be prepared by the user. When the whole row of the main busbar is tinned, the lap surface should be repaired and smooth, treated clean, coated with neutral petroleum jelly or other measures, and then reinforced with bolts.

The following items should be checked and tested before the product is installed and put into operation

(1). Check whether the paint on the cabinet has fallen off, and whether the cabinet is dry and clean.

(2) Whether the operating mechanism of the electrical components is flexible, and there should be no stuck or excessive operating force.

(3) Whether the main and auxiliary contacts of the main electrical appliances are reliable and accurate.

(4) Whether the ratio and polarity of the instrument indication and the transformer are correct.

(5) Whether the bus is well connected, and whether the insulation support parts, mounting parts and accessories are firmly and reliably installed.

(6) Whether the auxiliary contact meets the requirements, whether the core specification of the fuse is correct, whether the setting value of the relay meets the design requirements, and whether the action is reliable and accurate.

(7) Whether the contact of the circuit meets the requirements of the electrical schematic diagram.

(8) Whether the protection circuit system meets the requirements.

(9). The insulation resistance value measured with a 500 volt megohm meter shall not be less than 1MQ.

Warmly welcome the expert group to visit our company …

2023-04-21Qingming | spring breeze touching the face, everythin…

2023-04-05Arbor Day -- green and carbon reduction, total planti…

2023-03-12Baolai Electric bloom "her power" to make l…

2023-03-08Chairman of Baolai Electric Company was awarded the t…

2023-02-012023.1.19 love department of nursing home, Spring Fes…

2023-01-19Hangzhou entrepreneurs line company visit

2022-09-22President Yang of Suzhou College visited

2022-06-16